Bemis Manufacturing Company first turned to Milacron in the 1970s for machine solutions that produced a variety of plastics for its operations in both the consumer and commercial markets. From top-of-the-line household products like toilet seats, bidets, and faucets to healthcare solutions, after nearly fifty years in partnership, Milacron still delivers first-class innovation, technology, and service to the processor – a true lifecycle partnership in plastics.

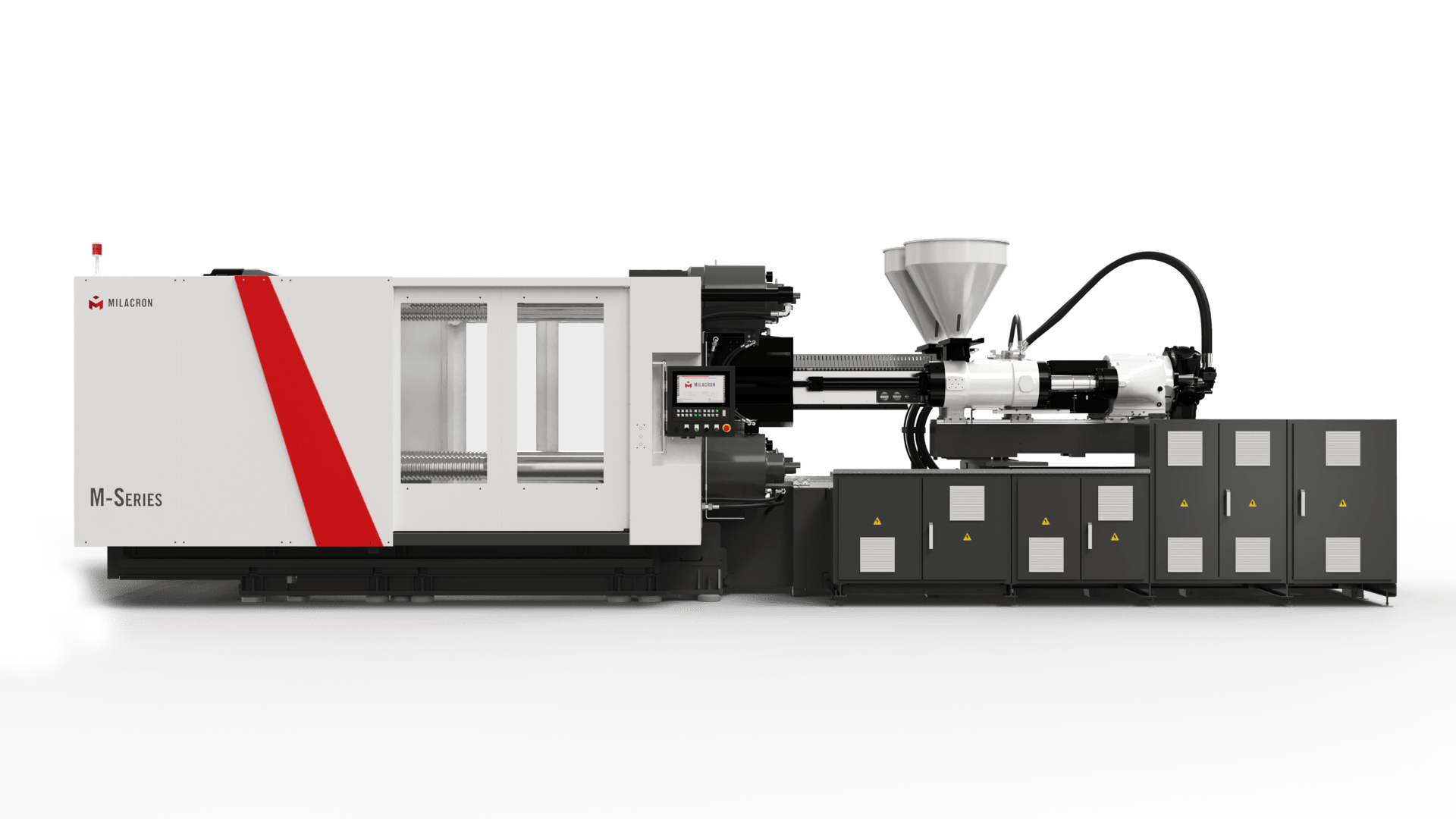

One of their first collaborative advancements, Milacron and Bemis pioneered co-injection technology to improve part performance and cost, while minimizing cycle time and production volume. Eventually, co-injection would help integrate PCR (post-consumer recycled) into the plastics manufacturing process, offering a more sustainable alternative for processors today. The Bemis fleet of Milacron solutions includes a variety of high-pressure injection molding machines, co-injection, and digital control technologies.

In recent years Bemis posed Milacron with the need for machine retrofits and digital upgrades in an effort to improve scrap rates and sustainability, as well as to save energy.

Today, Bemis manufactures products under its own brands and provides expertise to others, including private-label products and component parts for a variety of consumer, commercial, medical, and industrial markets in five countries around the world.

Milacron values the loyal partnership as the two companies continue to collaborate on advancements in plastics solutions that are groundbreaking and meet public demand.

#PartnerWithPossibility

Learn more about the solutions and possibilities this partnership has shaped.