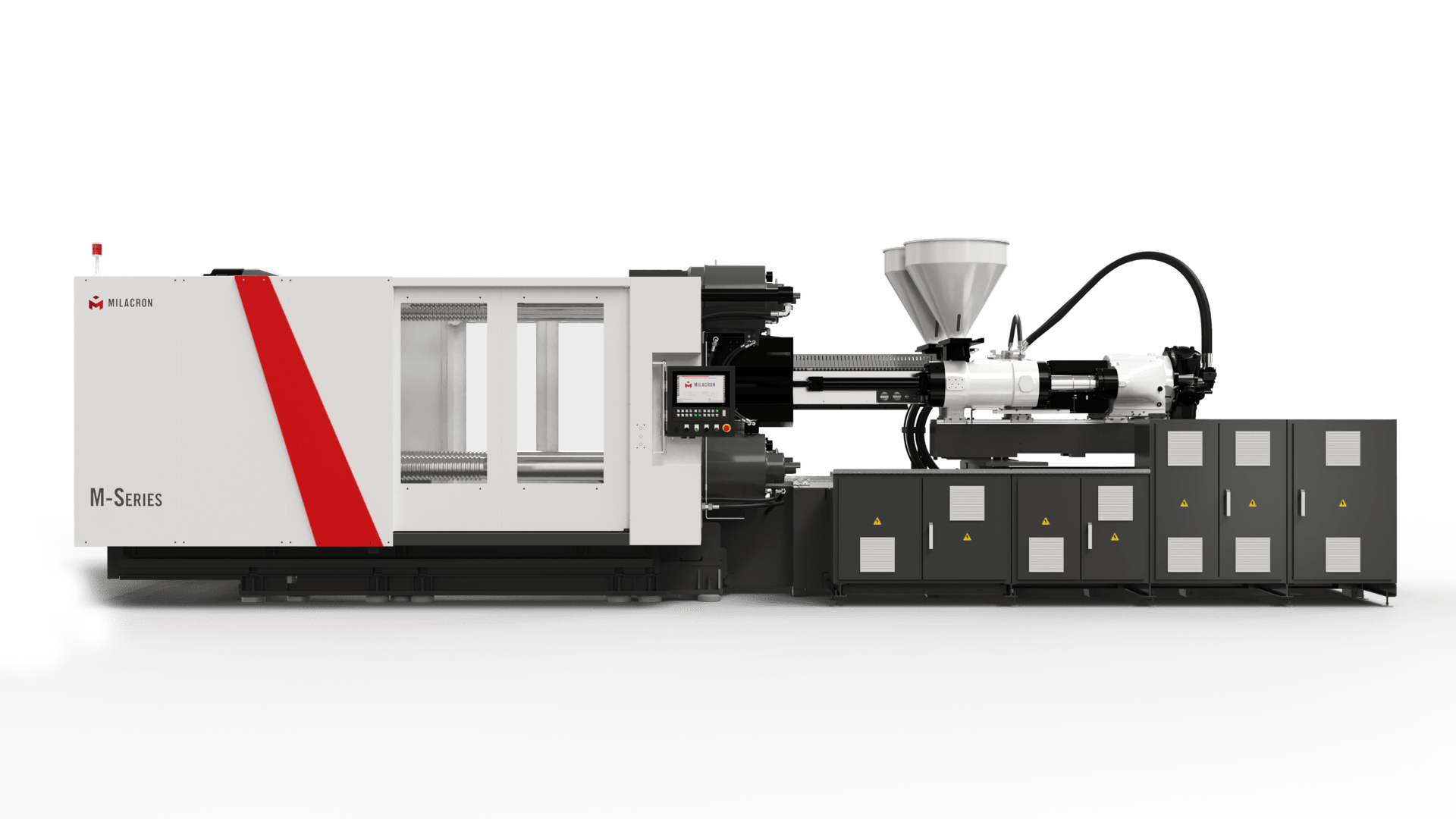

The universal M-Series delivers greater versatility, reliability, and reduced dry cycle time.

[BATAVIA, OH] February 29, 2024 – The Milacron M-Series marks a new milestone in the OEM’s plastics processing system development. The two-platen machine impresses with clamping forces ranging from 506 tons to 1,236 tons, demonstrating its flexibility for a wide range of applications.

Inclusive of six models, the M-Series builds on the company’s proven machine technology and sets new standards for medium-tonnage solutions. Powered by best-in-class Fanuc motors and drives, the M-Series’ versatility and performance serve to meet the demanding needs of global industries – from automotive and consumer goods to packaging and customer molders.

The new injection molding machine line is driven by a servo motor hydraulic system that offers improved specifications and all-inclusive performance, as well as integrated control. In addition, faster clamp speeds, reliable tonnage assembly, and improved mold and eject access for quicker mold changes deliver optimal productivity and space savings. Features also include a mechanically synchronized nut lock design, with industry-leading tie-bar spacing.

The improved clamp design of the M-Series provides a greaseless part drop area, precise alignment, and increased access to the ejection plate. Its lower centerline promotes an ergonomic design allowing for improved access to mold area and ease of mold maintenance. Additionally, an injection swivel provides easy screw removal.

“The M-Series not only demonstrates outstanding performance potential for a wide range of applications but was designed with customer need in mind,” said Alec Woll, M-Series Product Manager for Milacron. “It’s a workhorse that’s built to perform with bigger molds in a more compact package, but with less energy consumption.”

The bi-directional hydraulic pump of the M-Series is engineered for rapid pressure control while operating at a lower maintenance cost. The closed-loop system also improves cycle precision and repeatability. Leveraging the servo motors in combination with hydraulic components gives the M-Series exceptional repeatability compared to induction motor machines.

Energy savings and sustainability are at the forefront of this new Milacron offering that touts reduced dry cycle time, power consumption and less lubrication requirements. Additionally, all presses are compatible with the M-powered IIoT solution – a user-friendly, observational, analytical remote support service that delivers quality data/insights, improved production, decreased downtime, and increased profitability. Milacron integrates M-Powered onto all its new machines, including the M-Series, for free for the first 12 months of ownership.

“The M-Series was developed with customer needs as a baseline,“ said Woll. “Not only is it versatile and compact, but it can be used with a wide selection of injection unit sizes, barrels, and screws. It’s the epitome of an all-inclusive injection molding solution for a wide range of processors.”

Milacron will showcase the new M-Series at NPE2024 in Orlando this May at booth W1601.

Learn more about the advantages of the new Milacron M-Series in this short video rendering.

About Milacron

Milacron (www.milacron.com) is a global industry and technology leader in the manufacture of injection molding and extrusion systems. Milacron also manufactures and supplies machines, auxiliaries and components that complement its plastics processing machines and systems. The company’s 1,900 employees worldwide collaborate to provide a wide range of products for various plastics applications in industries such as automotive, construction, medical, telecommunications, material handling, packaging and many more. Milacron has long-standing relationships with more than 27,000 global customers in North America and India, as well as in Europe and many emerging markets, including Central and South America.

Milacron is an operating company of Hillenbrand Inc, an industrial company operating in over 100 countries and serving a variety of industries around the world. www.hillenbrand.com

CONTACT

Melanie Murray, Communications Specialist

[email protected] / 513.300.6020

Images

The universal M-Series delivers greater versatility, reliability, and reduced dry cycle time.

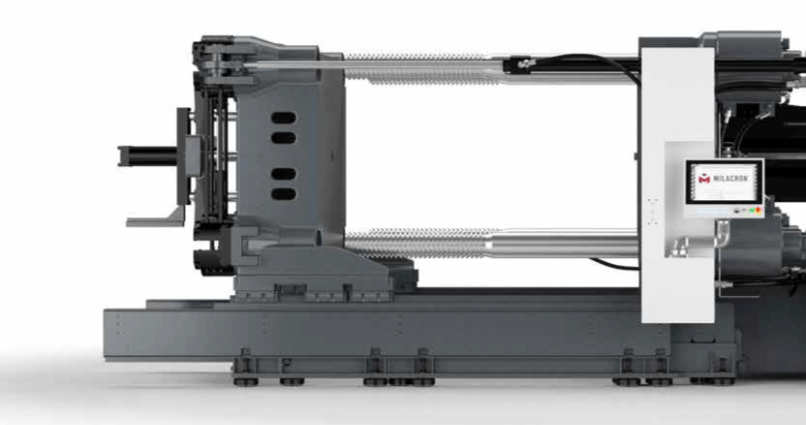

Clamp: Two-platen technology features rigid platen design with “open box” construction and reliable tonnage design.