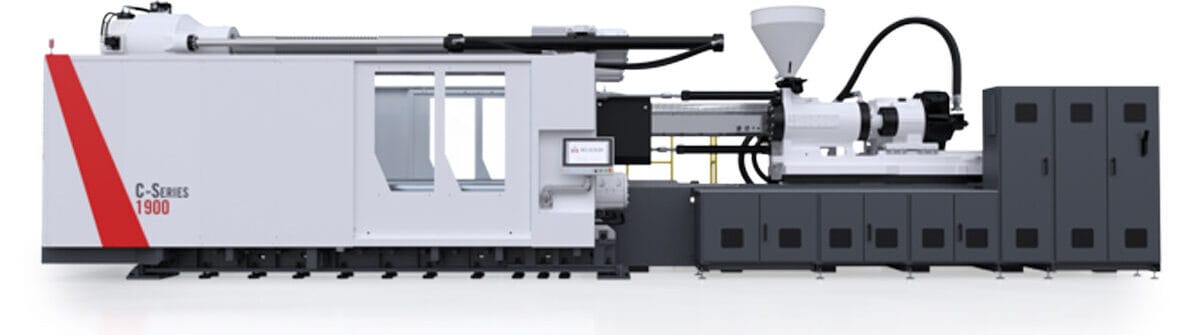

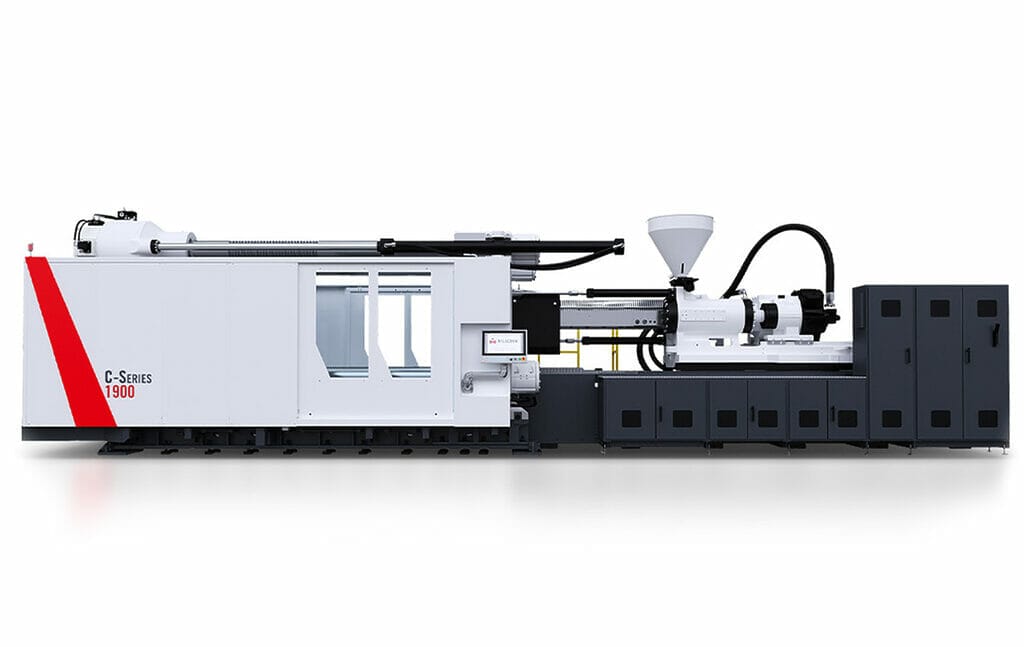

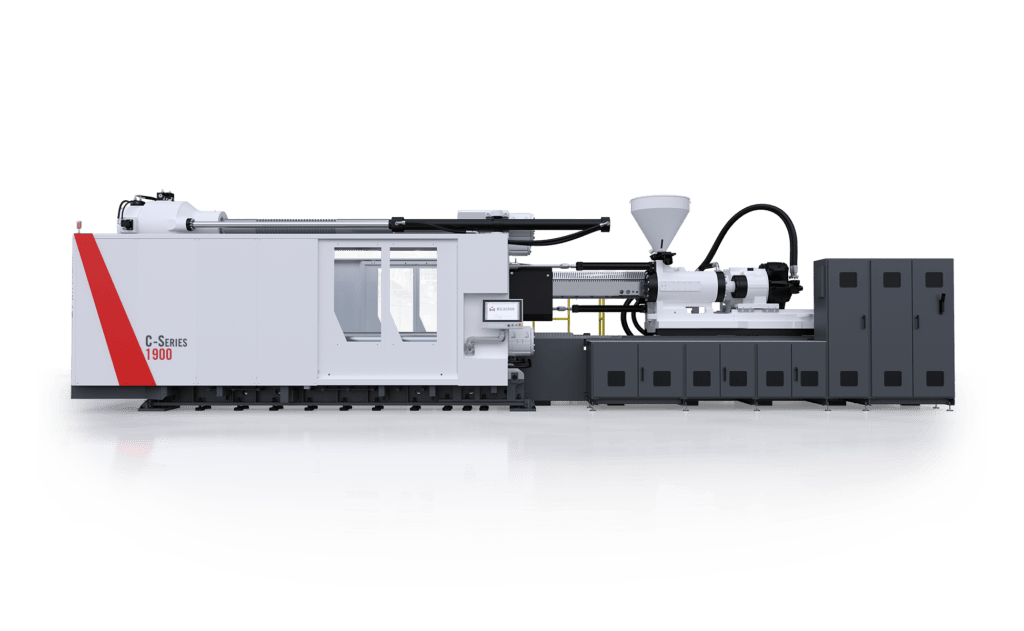

Overview

Developed with excellence as a baseline, the C-Series can be configured with a wide range of options across the product line to accommodate a large range of applications.

Milacron’s C-Series is the latest offering in our industry-leading large tonnage injection molding technology, designed to deliver the highest performance, precision, and flexibility. Enhanced machine specifications offer improved reliability, higher max mold weights, and faster clamp speeds. The C-series is powered by a reliable and energy-efficient hydraulic servo motor to meet the demanding market needs.

Built to excel, the C-Series offers a suite of machine options perfectly suited to your requirements. A variety of clamp, injection unit, and screw and barrel configurations are available to optimize the production of a large range of parts.

This is a true global machine in design, functionality and safety requirements. The C-Series is a large-part powerhouse that meets the demands of all the major market segments.

1500-6750 US

1300-6100 Metric

Available Tonnage

Noise Reduction

80%

Available In

Additional Info

Driven by industry-proven FANUC hydraulic servo-motors, the C-Series operates with a high degree of reliability at relatively lower decibel levels than previous machines. FANUC’s motor system also offers increased accuracy and precision by rotational control to a fraction of a degree. These motors are designed for demanding and diverse applications.

The highly efficient servo system decreases energy consumption by generating power during deceleration. The servo-motor also stops intermittently during the cycle to save energy. The FANUC servo system can extend the life of machine components by reducing energy flow and friction while also extending the life of oil and lubricants used in the machine by design.

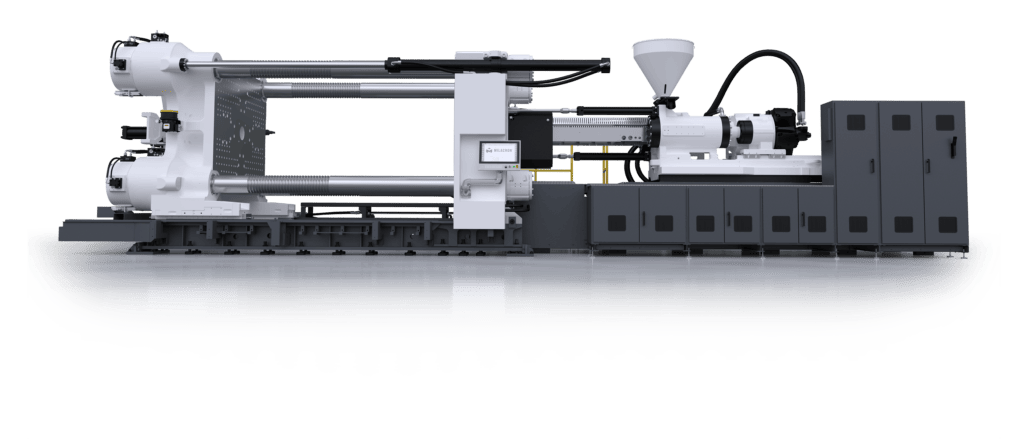

Features

The C-Series comes with predefined configurations that can increase the speed, accuracy, and capability in the large part market. Our integrated lock nut/tonnage system uniformly distributes clamp force and reduces mold wear while offering advanced control and improved parallelism. The C-Series features a rigid platen that matches center tonnage deflection and can accept increased max mold weights per platens. The twin cylinder injection unit distributes force evenly across the screw centerline and standard injection unit swivel for easy screw removal.

Available with The MOSAIC+ 21” multi-touch controller delivers fast processing, extensive data collection, and automation integration. Featuring a configurable layout, remote camera interface, Windows OS, self-diagnostic capabilities, and multi-level data protection, this solution enhances manufacturing reliability and adaptability. Globally launched in 2007, the MOSAIC platform’s evolution meets today’s manufacturing performance needs.

More than Machines

Milacron is the global leader in plastic processing solutions. We partner with our customers throughout the lifecycle of their equipment, helping them achieve their business goals. From sustainability consultation to training and advanced Industrial Internet of Things (IIoT) platforms, we focus on helping you leverage our industry-leading technology and talent to optimize your processes and maximize your production.

More than machines, Milacron is a partner that delivers possibilities.

Complete Plastic Process Line Solutions

For C-Series

Your Partner In Plastic Processing

Milacron transforms plastics into possibilities.

Contact us today to learn more about our complete plastic processing solutions.Downloads

C-Series