Overview

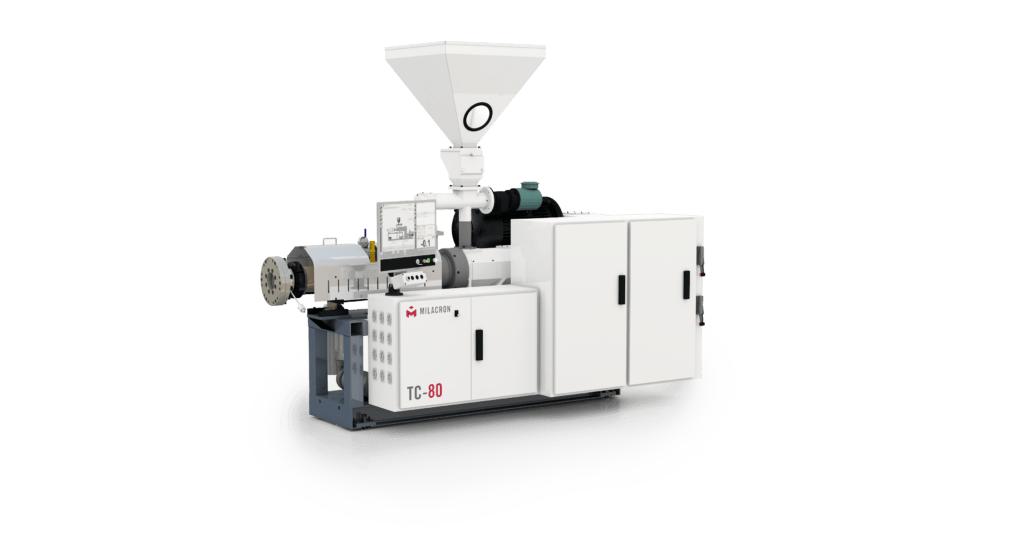

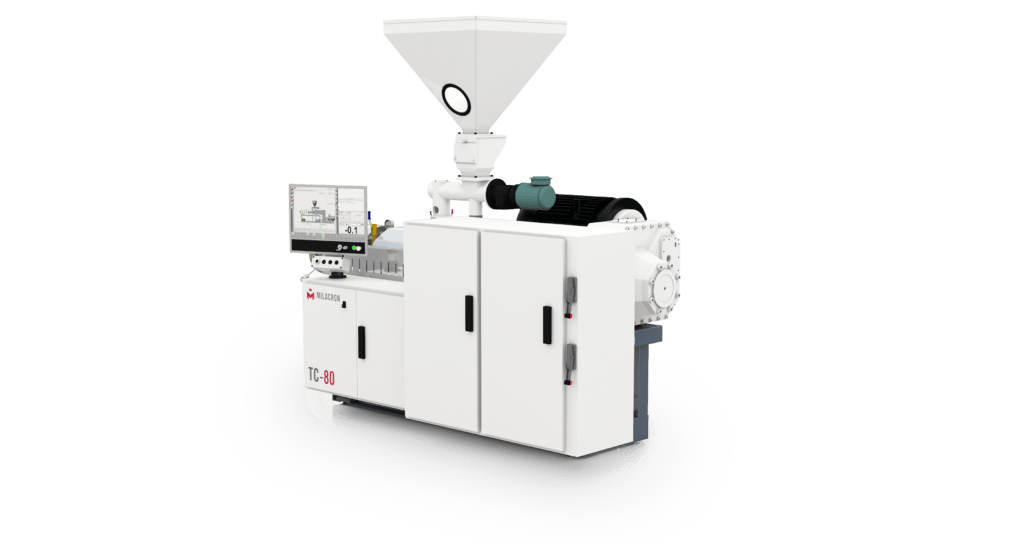

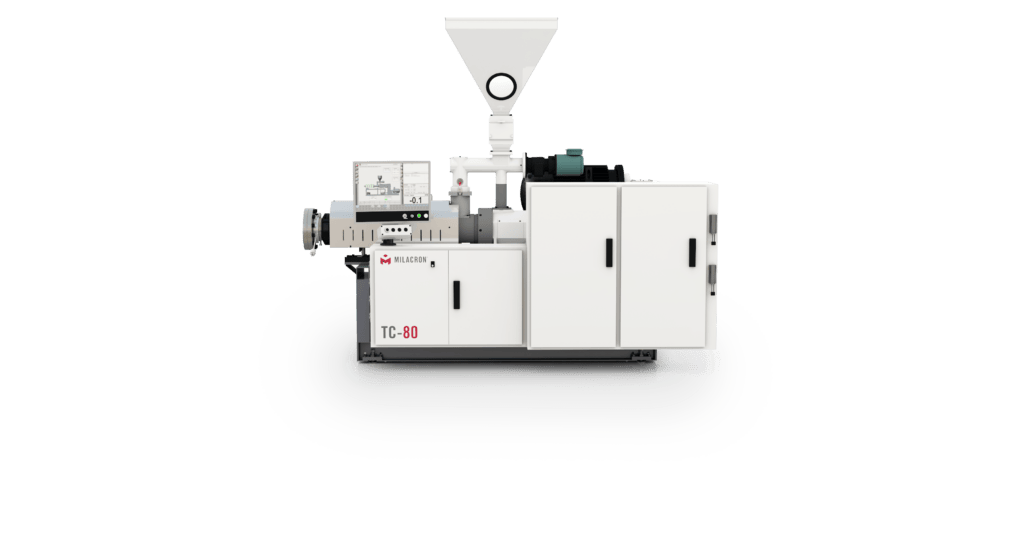

Available in twin conical (TC) or twin parallel (TP) screw configurations, Milacron Twin Screw Extruders are quality built for reliable, long-term operation. The TC system is engineered for flexibility. It has a wide range of options for virtually every process requirement. Designed for greater output, our TP system offers higher performance and helps increase production.

Our machines are capable of producing high torque while maintaining gentle plasticization. The high surface area, low shear screw designs also allow for efficient heat transfer. This makes our extruders ideal for heat and shear sensitive materials. Engineered to last longer, Milacron’s proprietary screw and barrel coating technologies deliver maximum wear protection and can lower life cycle costs.

Milacron’s twin screw extrusion systems offer a modular design making them suited for a wide range of applications and processes. The extruders are engineered and built in-house allowing us to deliver machines that can solve your processing challenges. From new and rebuilt extrusion barrels and screws, to pipe heads, dies and downstream equipment, you get reliable solutions that meet your unique needs.

Available In

Additional Info

Milacron’s screws and barrels are manufactured in-house and designed to extend the life cycle of your parts and help decrease overall downtime. Our screws and barrels come standard with our proprietary nitride coating. This coating provides superior hardness and wear characteristics compared to traditional nitride coatings. We also offer our exclusive tungsten clad lining. This fused interface helps provide superior heat transfer as compared to other barrel linings.

Produced from high quality DIN steel, our screws can be manufactured with even more coating options like chrome plate or a carbide encapsulation for more abrasive or demanding applications. We also offer customized screw designs specifically engineered to optimize your extrusion process.

Our team is capable of handling screw and barrel requests of virtually any size, application, and complexity for any extruder on the market.

Features

Milacron’s twin screw extruders have features that offer flexibility and exceptional value. Our machines come standard with high performance and increased load capacity gearboxes. We also offer gearbox re-builds and upgrades to help extend the life of your extruder.

A variety of drive motor systems are also available including our Total Enclosed Fan Cooled (TEFC) AC vector motor. A reliable, low maintenance solution, the TEFC is ideal for dusty manufacturing environments. Our TEFC is also one of our most energy efficient motors with an energy efficiency rating of greater than 90%. All our motors allow for quick access and easy maintenance.

Built to purpose, we offer a suite of extrusion options perfectly suited to your requirements. Our experienced team of process engineers can provide an evaluation of your existing equipment and develop extrusion solutions to meet your production needs.

More than Machines

Milacron is the global leader in plastic processing solutions. We partner with our customers throughout the lifecycle of their equipment, helping them achieve their business goals. From sustainability consultation to training and advanced Industrial Internet of Things (IIoT) platforms, we focus on helping you leverage our industry-leading technology and talent to optimize your processes and maximize your production.

More than machines, Milacron is a partner that delivers possibilities.

Complete Plastic Process Line Solutions

For Twin Screw

Your Partner In Plastic Processing

Milacron transforms plastics into possibilities.

Contact us today to learn more about our complete plastic processing solutions.Downloads

Twin Screw